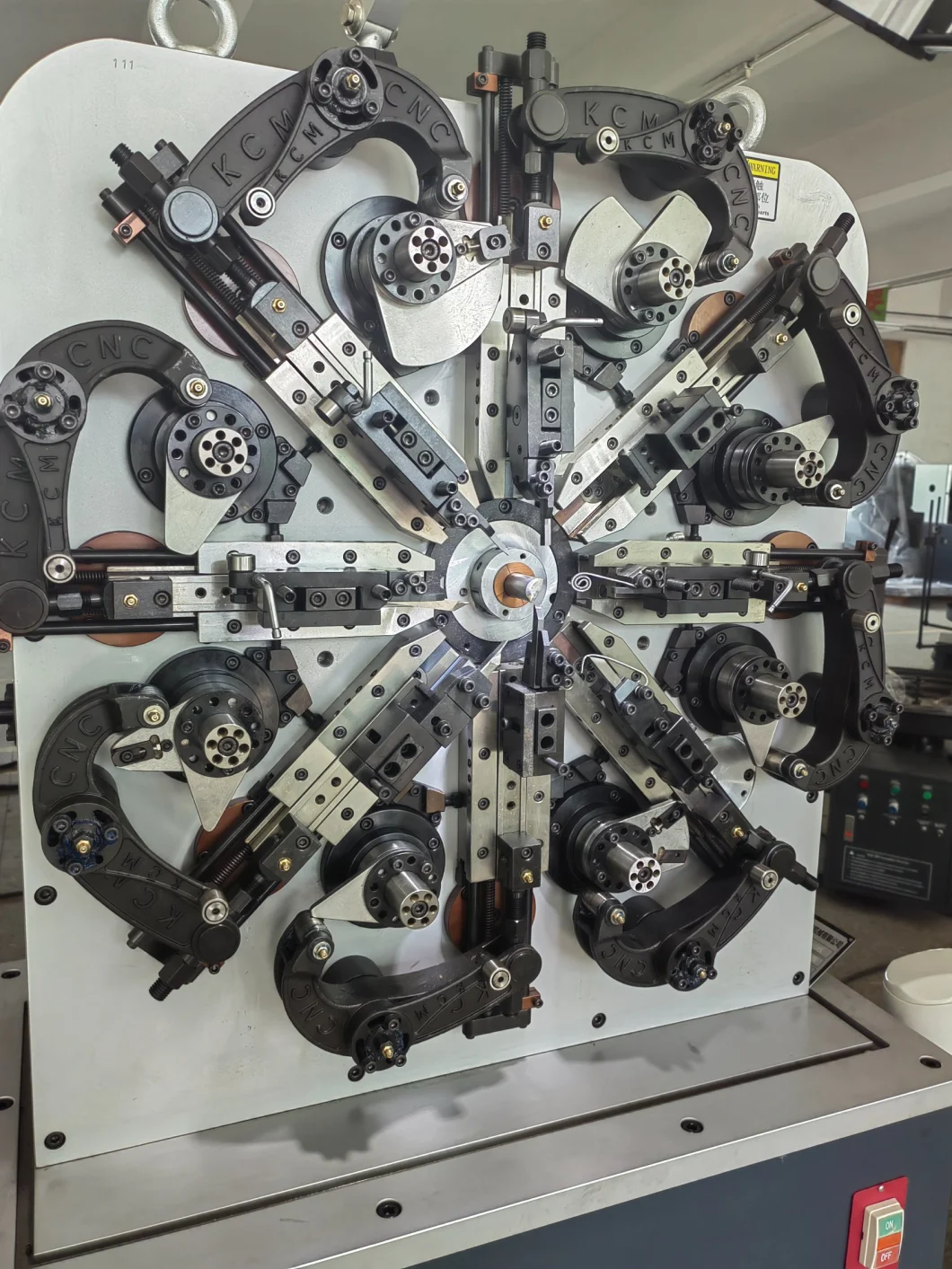

Custom Spring Coils & Torsion Spring Machine with Stainless Steel Hydraulic Bending Machine KCT-20B 3 Axis 2.0mm Spring Forming Machine

Basic Info

| Model NO. | KCT-20B |

| Max. Outer Diameter | 50mm |

| Max. Wire Feed Speed | 110m/min |

| Max. Production Rate | 70pcs/min |

| Feed Roller Group | 2 Groups |

| Feed Servo Motor | 2.7KW |

| Quill Servo Motor | 1.0KW |

| Cam Servo Motor | 2.7KW |

| Power AC | 3P 380V 50/60HZ |

| Weight | 1200KG |

| Dimension | 800*1100*1750mm |

| Trade Term | FOB/EXW/CIF/FCR |

| Lead Time | 7-35 Working Days |

| Application | Spring Making |

| Transport Package | Vacuum Packed& Wooden Case |

| Specification | IS0 9001: 2008, CE, SGS |

| Trademark | KCMCO |

| Origin | China |

| HS Code | 8463300000 |

| Production Capacity | 200 Sets/Year |

Product Description

KCT-20B 3/4 Axis CNC Versatile Spring Former MachineSpring Coiling Machine, 0.2-2.5mm CNC Flat Spiral Spring Coiling Machine

Flat Spring Scroll Spring Constant Force Spring Coiling Machine Making KCT-20B (0.2-2.5mm)

Buy China Flat Spiral Torsion Spring Machine Constant Force Spring Coiling MachineKCMCO Spring Precision Machinery distributes KCMCO Precision Flat Spring Scroll Spring Constant Force Spring Coiling Machine Making KCT-20B (0.2-2.5mm) to companies across the world. This model is equipped with a Windows 7 operating system, remote monitoring, USB port and touch screen surface. With a maximum of 3/4 axes working independently, it can have an optional servo spinner and hydraulic cutter installed.1. This type of versatile spring making machine is of functions of both wire forming and spring making.2. The servo motors is imported from Japan, and it have totally 3/4 axis fitted on it. The axis could work simutanously or alone. They are controlled accurately by our most advanced computer system introduced from Taiwan.3. It have wire rotation on the back of the machine. Thus allow various movement of wire material and make spring mafacturing process more precise as well as stable in comparision with other CNC spring machines known in market today.4. We adhere to the principle of cost-saving, and performance-improvement, in a word, absolutely it will be your perfect choice for spring making.

CNC Spring Coiler Spring(0.2-2.5mm) KCT-20B Auto Coil Spring Flat Spiral Springs & Buy Door Spiral Spring Steel Flat Constant Torsion Coil Clip Spiral Torsion Spring Machine

1. KCT-20B CNC has 3/4 axis which can work in high speed single-step or synchronously.2. Equipped with right or left-handed winding blade rest.3. The operator software is advanced, yet very easy to use, enabling machine setters to start producingSprings in the shortest amount of time.4. Spring programs can be saved to the computers internal memory.5. Computer interface displayed in Chinese and English makes the operation easy.6. Can make sample by hand wheel.7.External Spring Length Gauge is optional.8.Precision, Speediness and Stability.9.Top 3 Manufacturing Vendor in leading spring industry in China.10.Best Service and High Quality and Online Supports.

Product Parameters| Model No | KCT-20B |

| Axes Number | 3/4 (Max 18 Axes) |

| Wire Diameter | 0.2-2.5mm |

| Max. Outer Diameter | 50mm |

| Max. Feeding Length | unlimited |

| Feeding Setting Value | +/-0.01- +/-9999.99mm |

| Wire Feeding Speed | 0-110M/Min |

| Max. Production Rate | 70pcs/Min |

| Cam Setting Value | +/-0.1 - +/-359.9 |

| Power AC | 380V 50/60HZ |

| Dimensions(LxWxH) | 800*1100*1750mm |

| Machine Weight | 1200kg |

Specification for KSJ-1000

| Specification for KSJ-1000 | |

| Model No | KSJ-1000 |

| Max Capacity of Load | 1000KG |

| Max Speed of Table | 50rpm |

| Diameter of Table | 2000mm |

| Motor | 4.0KW |

| Frequency Changer | 3.7KW |

| Power AC | 220V 50HZ |

| Weight | 1000KG |

| Dimension | 2900*2200*1365MM |

| Remark: | |

| The diameter of KSJ-1000 is just for reference only, it's up to actual production. | |

Products Description

1. Long service-life2. Good hardness3. Good resistance to both high and low temperatures4. Can be used in various corrosive mediums5. Main material: Carbon spring steel, alloy spring steel,Refractory steel, stainless steel, high temperatureResisting alloy, corrosion-resistant alloy and bronze6. Widely used in automobiles, motorcycles, electricalAppliances, telecommunication, communication,Aviation, space and other civil fieldsNote: If the spring needed for your application cannot be found in our website, .Send below information or drawing to my email. We can fabricate it for you1. Wire diameter2. Material of products3. Free length4. Maximum outside diameter, minimum inside diameter5. Number of coil.

Packaging Methods:

1.One Tooling Box with all drivers and different kinds of screws and other stuffs.2.Standard Fumigated Wooden Case&Vacuum Packing3.Inside with Bubble Foaming Packed.4.Complete Closed Vacuum Paper with Hot Sealing Machine.5.The outside of wooden box have the signal to load safely.

Dongguan Kaichuang Precision Machinery (referred to as "Kaichuang spring machine") is the China Mechanical Engineering Society of spring technology group members, was founded in 2003, is the current professional set research and development, production and sales of CNC spring machine as one of the largest spring machine manufacturers, models covered the φ0.15-8.0mm between the more than 20 different types of computer spring machine products, which covers CNC spring machine, such as computer compression spring machine, universal spring machine and Camless spring machine, universal spring machine and Camless spring machine. And supporting a variety of specifications of the automatic wire feeding machine frame and other equipment, but also to provide spring machine tools or accessories (standard or non-standard) and other related services.At present, our leading products are: KCT-1280WZCNC, KCT-1260WZCNC, KCT-1245WZCNC and KCT-1120WP CNC Camless spring machine series; KCT-0535WZCNC, KCT-0520WZCNC, KCT-35WCNC and KCT-20BCNC CNC universal spring machine series; KCT-680CNC,KCT-660, KCT-826CNC, KCT-808CNC, KCT-540CNC, KCT-35ACNC, KCT-26ACNC and KCT-8C CNC computer compression spring machine series; KSJ-2500, KSJ-1500, KSJ-1000 , KSJ-400, KSJ-200 and KSJ-100 automatic wire feeding decoier series. In addition, also supporting a variety of CNC grinding machine (computer grinding machine), back to the furnace series and spring machine tools or accessories and other services.

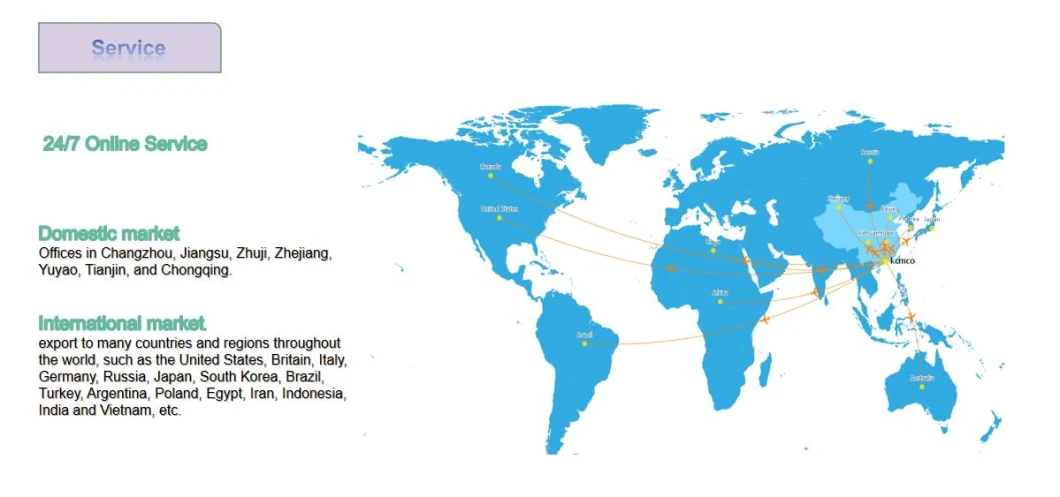

After Sales ServiceOnce you purchase our spring machine, then our great service to you will begin. We will arrange our engineers and mechanics to provide you online free training with 24-hour services and supports.If you are in need of our engineers and mechanics to your country for off-line installation and practical training, then you just need to arrange the accommadation and transportation as well as standing of living costs for it. Whenever you have any further questions, we will be always with you since your purchasing machine.With more than 30 years of experience in leading spring machines, we have become one of top 3 manufacturing vendors in this industry and our customers cover more than 30 countries and regions, such as the United States, Britain, Italy, Germany, Russia, Japan, South Korea, Brazil, Turkey, Argentina, Poland, Egypt, Iran, Indonesia, India, Vietnam and so on.

If you have not found it yet, then we still have other related products for your reference:1.Camless CNC Mult-Axis Spring Machines:2.CNC Spring Coiling Machines:3.Wire Bending&Forming Machine:

At present, our leading products are: KCT-1280WZCNC, KCT-1260WZCNC, KCT-1245WZCNC and KCT-1120WP CNC Camless spring machine series; KCT-0535WZCNC, KCT-0520WZCNC, KCT-35WCNC and KCT-20BCNC CNC universal spring machine series; KCT-680CNC,KCT-660, KCT-826CNC, KCT-808CNC, KCT-540CNC, KCT-35ACNC, KCT-26ACNC and KCT-8C CNC computer compression spring machine series; KSJ-2500, KSJ-1500, KSJ-1000 , KSJ-400, KSJ-200 and KSJ-100 automatic wire feeding decoier series. In addition, also supporting a variety of CNC grinding machine (computer grinding machine), back to the furnace series and spring machine tools or accessories and other services.

Q1: How to place the order? A1: You can place the order by email us or reach us directly with your contact information. Q2: What is the MOQ?A2: One set. The more you have, the better price you will get. Q3: What is the payment term? A3: The payment term is 30% deposit as PO confirmation, and 70% before the shipment.We also accept other payment term. Q4: What is the delivery time? A4: Normally the delivery time of the machine is 30-40 working days after receiving deposit.But it all depends on machine models you place the order. Some of them could be shipped within 7 working days if we have that machine available in our warehouse. Q5: What is the guarantee period of the machine? A5: The guarantee period is one year for the core components like motor from the date of B/L.