German Technology Taiwan Quality High Speed High Precision Mini China Hobby Cheap Price 3 Axis Metal Steel CNC Milling Machine

Basic Info

| Model NO. | BF-1370V |

| After-sales Service | Provide |

| Warranty | 1 Year |

| Application | Metal |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Controller System | Mitsubishi M80 /Fanuc 0I-Mf/Siemens 828d |

| Rapid Feed | 30m/Min |

| Spindle Speed | 12000/15000/18000rpm or Higher |

| Rotary Table | 4 Axis/5 Axis Optional |

| Table Size | 1450*700mm |

| Transport Package | Wooden Package |

| Specification | 3300x3200x3140mm |

| Trademark | Baofeng |

| Origin | China |

| HS Code | 84571010 |

| Production Capacity | 5000 |

Product Description

Specification| TRAVEL | |

| X/Y/Z axis travel | 1300*700*700mm |

| Spindle nose to table | 140-840mm |

| Spindle center to column | 750mm |

| Positioning accuracy | ±0.003/300mm |

| Repeated positioning | ±0.002/300mm |

| Spindle | |

| Spindle taper | BBT40 |

| Spindle transmission | Direct drive |

| Spindle speed | 12000 rpm/min |

| Controller | |

| CNC control | Fanuc 0i-MF |

| Spindle motor | 11/15 kw 12000 rpm/min |

| X/Y/Z motor | 3.0/3.0/3.0kw |

| Table | |

| Table size ( W x L ) | 1450x700mm |

| T slot | 5-18x152.5mm |

| Table load | 1500kg |

| Feed | |

| X/Y/Z rapid feed rate | 30/30/30m/min |

| X/Y/Z linear guideway | 45/45/45mm |

| X/Y/Z ball screw | 10mm-ball |

| MACHINE DIMENSION | |

| Dimension | 3300x3200x3140mm |

| Weight | 10500kg |

Main parts list:

| Item | Brand |

| Spindle | Taiwan-Spintrue |

| Spindle bearing | Japan-NSK |

| Ball screw | Taiwan-PMI |

| Linear guideway | Taiwan-PMI |

| Pneumatic parts | Japan-Mitsubishi |

Optional configuration:

- SIEMENS/FANUC/Mitsubishi CNC Controller- 4th/5th axes rotary table- Chip conveyor- Tool setter- Oil mist collectorDescription

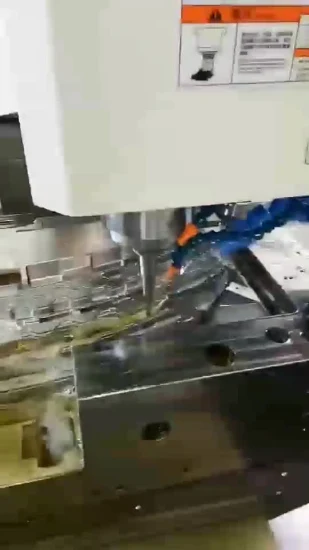

It can continuously complete drilling, milling, tapping, boring, reaming, and other machining processes by once clamping and can complete coordinate boring and fine machining of complicated parts and molds accurately and efficiently.This series of VMC vertical machining centers are widely used for mass production of small and medium-sized cabinets, covers, panels, shells, and plates in high-precision molds, automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, precision metal products, precision mold products, and machinery manufacturing industries.

It adopts an inverted T-shape design, which is usually used in the horizontal plus surface, this structure has better stability and rigidity than the traditional vertical machine center base.

With a double-layer box structure design, the weight will be 30% more than the single-layer structure, and the stability, deformation resistance, and rigidity of the machine body will be much higher than the ordinary single-layer structure.

why choose us

Reason 1. High Precision & High Stability

Baofeng factories are equipped with full sets of large-scale high-precision mother machines, grinding machines, and other production equipment, as well as full sets of high-precision testing equipment, such as Renishaw's laser interferometer, collimator, ball bar, Ketek dynamic balancer, Carl Zeiss three coordinates, Etc. to ensure that each machine handed over to the customer maintains high accuracy and reliability.Reason 2. Well-known brandBaofeng is a state-level high-tech enterprise with dozens of patentsFamous in the industry for the quality of machines comparable to Taiwan machines.Reason 3. SpecialtyFocused on making CNC machines for more than 10 years. An integrated process from research and development, design, assembly, sales, and after-sales has been realized. There are currently three large modern production bases as well as an application training center. can satisfy customers' requirements better.Reason 4. On-timeWe always deliver machinery on time so that our customers do not need to waste extra time waiting. We also respond to our customers the first time in order to satisfy customers' requirements.Reason 5. experience

we have accumulated rich experience in manufacturing and service. Products include vertical machining centers, horizontal machining centers, large gantry machining centers, engraving and milling machines, drilling and tapping machines, etc.; the sales network covers many countries in Europe, America, Asia, and Africa.

FAQ1. How can I choose the most suitable machines?

A: Please tell me your specifications, we can choose the best model for you, or you can choose the exact model.You can also send us the products drawing, we will choose the most suitable machines for you.2. What are your trade terms?A: FOB, CFR, and CIF are all acceptable.3: What are the Payment Terms?

A: 30% deposit T/T in advance, 70% balance payment before shipment; Irrevocable LC at sight.4. What's the MOQ?

A: please negotiate with us.If you need a machine with your own specification, logo, packing, etc,